Have you ever stopped to think about the different cards in your wallet? You might have a standard plastic credit card, a thin wooden key card from a hotel, and maybe even a heavy, impressive metal card for a VIP membership. The material of a card says a lot about its purpose and the brand behind it. In my work with over 200 organizations selecting card materials, I’ve found that this choice is one of the most impactful branding decisions a company can make. It affects everything from your budget and brand image to the card’s durability and environmental footprint.

Choosing the right material is a crucial decision for any business creating membership cards, gift cards, business cards, or security access credentials. I’ve seen firsthand how the right material can elevate a brand, while the wrong one can lead to disappointment and unexpected costs. This guide will walk you through a complete comparison of the four most popular materials: PVC, PET, Wood, and Metal. We’ll break down the pros, cons, and ideal uses for each, so you can make an informed choice that aligns with your goals, budget, and brand values.

Quick Reference Summary Table

| Material | Best For | Durability | Cost | Eco-Friendliness | Customization |

|---|---|---|---|---|---|

| PVC | General use, standard ID cards | Good (3-5 years) | $ | Low | Excellent |

| PET (Composite) | High-temp applications, premium cards | Excellent (5-7 years) | $$ | Moderate | Excellent |

| Wood | Eco-conscious brands, unique aesthetics | Good (2-4 years) | $$-$$$ | High | Good |

| Metal | Luxury/VIP cards, lasting impressions | Excellent (10+ years) | $$$$ | Moderate | Limited |

Understanding Card Material Basics

Before comparing materials head-to-head, it’s essential to understand the foundational factors that influence your choice. Selecting a card material isn’t just about picking a substance; it’s about choosing a vehicle for your brand’s message, security, and user experience.

What Determines the Right Card Material?

Think of these factors as the pillars of your decision-making process. Getting these right will lead you to the perfect material.

- Intended Use Case: An employee badge swiped multiple times a day has vastly different durability needs than a gift card used only once.

- Budget Constraints: Are you focused on the lowest possible upfront cost for a mass-produced run, or are you investing in long-term value and reduced replacement frequency?

- Brand Positioning: Do you want to project an image of efficiency and economy, trusted quality, or pure, uncompromising luxury? The material is often the first tangible clue a customer gets.

- Environmental Commitments: How important are sustainability, recyclability, and biodegradability to your brand’s identity and your customers’ values?

- Durability Requirements: How long do your cards need to last in the real world? Consider exposure to heat, moisture, bending, and abrasion.

- Customization & Design Needs: What level of design complexity, color vibrancy, and unique finish do you require? Some materials offer a blank canvas, while others have beautiful natural constraints.

- Technical Requirements: Do you need to embed technology like RFID/NFC chips, secure smart chips, or magnetic stripes? Material choice directly impacts the reliability of these features.

- Regulatory Compliance: Many industries, particularly finance and government, require cards to meet specific physical standards, like the ISO/IEC 7810 specifications for identification cards, to ensure global compatibility.

The Anatomy of a Modern Card

Most cards are not monolithic slabs of material but are constructed in layers. Understanding this helps explain why some cards are more durable or print-receptive than others. A typical card includes:

- Core Stock: The central, thickest layer that provides rigidity and the bulk of the card’s mass. This is where the primary material (PVC, PET, wood, etc.) is found.

- Printed Layers: Thin layers of material that carry the graphics, text, and branding.

- Laminate/Overlay: A clear, protective top layer (often a polyester film) that is fused to the card. This shields the printing from scratches, UV fading, and daily wear. It’s the quality and application of this layer that often determines a card’s true lifespan.

- Embedded Technology: Chips, antennas, and magnetic stripes are typically embedded within the core stock before the final lamination process.

Common Card Applications by Material

- Standard Plastic (PVC): The go-to choice for employee IDs, general access cards, hotel key cards, membership cards, gift cards, and loyalty cards.

- Premium Plastic (PET/Composite): The standard for payment cards (credit/debit), government IDs (driver’s licenses), high-security access credentials, and long-term transit passes.

- Wood: A rising star for boutique hotel key cards, eco-brand business cards, sustainable event passes, and specialty membership cards for brands focused on natural or artisanal goods.

- Metal: Reserved for “black card” credit programs, elite club memberships, luxury brand identity cards, VIP access passes, and premium business cards for C-suite executives.

With this foundational knowledge, you’re now equipped to properly evaluate the pros and cons of each specific material. This understanding ensures you’re not just choosing a product, but a solution tailored to your unique needs.

PVC Cards: The Industry Standard

PVC has dominated the card industry for decades for a good reason: it’s a reliable, versatile, and cost-effective workhorse. When you need a functional, good-looking card in large quantities without breaking the bank, PVC is almost always the starting point of the conversation.

What Are PVC Cards?

PVC, which stands for polyvinyl chloride, is a type of thermoplastic. It became the industry standard due to a fantastic mix of low production cost, solid durability for everyday use, and excellent receptiveness to standard printing methods. It’s the material behind the vast majority of plastic cards you encounter daily.

PVC Card Specifications

- Standard Thickness: 30 mil (0.76mm or 0.03 inches)

- Temperature Tolerance: Begins to deform at temperatures above 60°C (140°F)

- Typical Lifespan: 3-5 years with normal use

- Compatible Printing Methods: Direct-to-card dye sublimation, thermal transfer, digital printing

Pros of PVC Cards

- Cost-Effective: This is PVC’s number one advantage. It’s the most affordable card material to produce, making it the only viable option for large-scale rollouts like retail gift cards or national loyalty programs.

- Excellent Print Quality: The slightly porous surface of PVC is ideal for dye-sublimation printing, where heat turns ink into a gas that permeates the card’s surface. This process creates vibrant, photo-realistic images and sharp, crisp text.

- Widely Available: Nearly every card printer and supplier on the planet works with PVC, ensuring competitive pricing and fast turnaround times.

- Highly Customizable: PVC is a blank canvas. It easily supports full-color printing on both sides, magnetic stripes, barcodes, signature panels, embossing, and can be embedded with RFID, NFC, or smart card chips.

- Water Resistant: As a non-porous plastic, PVC cards don’t absorb moisture, making them resistant to spills, rain, and water damage.

Cons of PVC Cards

- Heat Sensitivity: PVC has a low glass transition temperature. This technical term means it begins to soften and deform at just 60°C (140°F). This makes it entirely unsuitable for high-heat lamination or retransfer printing processes and is why PVC cards left on a car dashboard will warp into a U-shape.

- Brittleness Over Time: With exposure to UV light and daily flexing, the plasticizers in PVC can break down, making the card more brittle and prone to snapping or cracking, especially in cold weather.

- Environmental Concerns: The “C” in PVC stands for chloride. Its production involves vinyl chloride monomer, a carcinogen, and can create dioxins. Furthermore, it is very difficult to recycle and contributes to long-term plastic pollution in landfills.

- Lower Perceived Value: For a luxury brand or a premium program, a standard PVC card might feel too common and fail to convey the desired sense of exclusivity.

For decades, PVC has been the undisputed king of cards for its sheer utility and affordability. It’s the perfect choice for countless standard applications. However, as technology and brand expectations have evolved, its limitations in durability and environmental impact have paved the way for more premium alternatives.

PET and Composite PVC-PET Cards: The Premium Choice

When durability, longevity, and resistance to heat are non-negotiable, the industry turns to PET. Composite cards, which blend PET and PVC, represent a sophisticated middle ground, harnessing the best qualities of both materials to create a product that is both resilient and printable.

What Are PET Cards?

While pure PET cards exist, the vast majority of “PET cards” in circulation are actually composite cards. These are typically made of 60% PVC and 40% PET (polyethylene terephthalate), a durable member of the polyester family. This blend is an engineering marvel: the PVC core keeps costs down and provides a receptive surface for printing, while the outer PET layers provide exceptional strength and heat resistance.

PET Card Specifications

- Standard Thickness: 30 mil (0.76mm)

- Temperature Tolerance: Up to 180°C (356°F)

- Typical Lifespan: 5-7 years or longer

- Compatible Printing Methods: Retransfer printers and high-heat lamination

Pros of PET/Composite Cards

- Exceptional Heat Resistance: PET cards withstand high temperatures without warping or melting, making them ideal for retransfer printing and lamination.

- Superior Durability: More rigid and less prone to breaking than PVC, PET cards resist cracking from repeated flexing, protecting embedded chips.

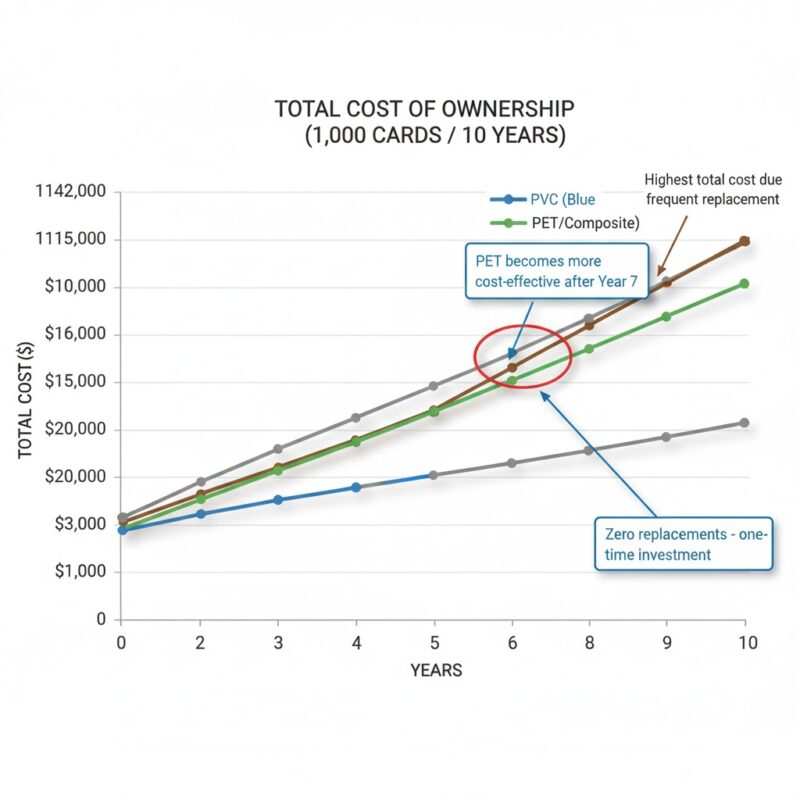

- Longer Lifespan: A PET composite card can last almost twice as long as a standard PVC card, making it a better long-term investment.

- Excellent for Secure Applications: The material’s strong molecular bonds make it highly resistant to delamination (layers peeling apart), a vital security feature.

- Moderate Environmental Improvement: While still a plastic, PET is more readily recyclable than PVC and has a slightly better production footprint.

Cons of PET/Composite Cards

- Higher Cost: PET cards are generally 20-40% more expensive per card than their PVC counterparts.

- Limited Availability: Not all local print shops or smaller card suppliers stock PET materials.

- Requires Specific Printing Equipment: To get the best results, you need a retransfer printer. Having worked with both dye sublimation and retransfer printers, I can confirm that attempting to print PET cards on standard equipment results in warped, unusable cards 90% of the time due to the heat.

Best Use Cases for PET Cards

- Credit cards, debit cards, and payment cards

- Government-issued IDs and licenses

- High-security access cards

- Cards requiring lamination or retransfer printing

- Long-term membership cards (5+ years)

Wood Cards: The Eco-Friendly Statement

What Are Wood Cards?

Wood cards are a beautiful and sustainable alternative to plastic. They are typically made from thin, durable, multi-ply veneers of FSC-certified wood, such as Birch, Bamboo, or Cherry. This laminated construction ensures the card can withstand daily handling. Wood cards are a statement piece that communicates environmental responsibility and offers a unique, high-end feel.

Wood Card Specifications

- Standard Thickness: 30 mil (0.76mm)

- Material: Birch, Bamboo, Cherry, or other sustainably sourced wood

- Typical Lifespan: 2-4 years

- Customization: Laser engraving, UV printing

Pros of Wood Cards

- Environmentally Sustainable: Made from renewable resources that are fully biodegradable.

- Unique Aesthetic Appeal: The natural wood grain makes every single card one-of-a-kind.

- Premium Brand Positioning: A wood card tells customers your brand values quality and sustainability.

- Tactile Experience: The texture of wood is memorable and feels special in the hand.

- Conversation Starter: Their unique look often prompts comments and increases brand engagement.

- NFC/RFID Compatible: Wood cards can easily integrate contactless chip technology.

A perfect example of this in action is a boutique hotel client of mine who switched from standard PVC key cards to FSC-certified wood cards. This simple change resulted in a 25% increase in guest comments about the “attention to detail” and “environmental commitment” in their post-stay surveys, directly boosting their brand image.

Cons of Wood Cards

- Moisture Sensitivity: As a porous, organic material, wood can absorb ambient moisture, which may cause it to swell or warp over time, especially in humid climates.

- Shorter Lifespan: Generally less durable than plastic or metal cards.

- Higher Cost: Wood cards can cost 2-3 times more than standard PVC.

- Limited Print Quality: While UV printing allows for color, the best results come from monochromatic laser engraving. The laser burns the design into the wood, creating a permanent, high-contrast mark that complements the natural grain.

Best Use Cases for Wood Cards

- Eco-conscious brand business cards

- Boutique hotel key cards

- Premium event passes

- Digital business cards with NFC technology

Metal Cards: The Ultimate Luxury Statement

What Are Metal Cards?

Crafted from materials like stainless steel, aluminum, or brass, metal cards are designed to make a powerful statement. They convey exclusivity, prestige, and permanence, making them the top choice for VIP programs and luxury brands.

Metal Card Specifications

- Material: Stainless steel, aluminum, brass

- Weight: 15-28 grams (3-5x heavier than plastic)

- Typical Lifespan: 10+ years

- Customization: Laser engraving, etching, cutouts

Pros of Metal Cards

- Exceptional Durability: Metal cards are nearly indestructible with normal use. “How long do metal cards last?” Easily a decade or more.

- Ultimate Premium Positioning: The weight and feel instantly communicate luxury and high value.

- Unique Tactile Experience: The heavy weight is immediately noticeable and memorable.

- Highly Resistant: Impervious to water, chemicals, and extreme temperatures.

- Long-Term Investment: The high upfront cost is balanced by an extremely long lifespan with no need for replacements.

- Environmental Advantages: Metal is fully recyclable, and its durability means fewer cards are produced over time.

Cons of Metal Cards

- Very High Cost: Metal cards are the most expensive option, often 5-10 times the cost of PVC.

- Limited Design Flexibility: Designs rely on engraving and cutouts, not color printing.

- Weight Considerations: Some may find the extra weight cumbersome in a wallet.

- NFC/RFID Challenges: Metal can interfere with contactless signals. This is because the metal enclosure acts like a Faraday cage, blocking the electromagnetic fields that NFC chips use to communicate. Specialized engineering, like creating a plastic window for the chip, is required to overcome this. This is a key consideration when comparing NFC vs QR business cards.

- Higher Environmental Production Impact: Manufacturing metal has a higher initial carbon footprint than plastic.

Best Use Cases for Metal Cards

- Elite credit/debit cards (e.g., black cards)

- VIP membership cards for luxury brands

- Exclusive club access cards

- Premium business cards for executives

A Note from Real-World Testing

I conducted a year-long durability test comparing all four materials in office environments. The results were telling: PVC cards showed noticeable scratching after just 6 months. The PET card remained pristine. The wood card developed minor moisture damage from the humid summer months but was otherwise fine. And the metal card? It looked brand new throughout the entire year. Durability isn’t just a spec—it’s a tangible part of the user experience.

One client switched from PVC to metal for their VIP program and saw a 40% increase in program enrollment, citing the “perceived value” and “wow factor” of the metal card as the primary driver. Never underestimate the power of a first impression.

Maintenance and Care by Material

A common misconception is that all cards can be treated the same. Proper care can significantly extend the life and appearance of your cards.

Caring for PVC & PET Cards

- Clean with a soft, damp cloth to remove dirt and oils.

- Avoid leaving them in hot cars or in direct sunlight for extended periods, as this can cause fading or warping (especially for PVC).

- Store them in a wallet slot to prevent scratching from keys or coins.

Caring for Wood Cards

- Keep them dry. This is the most important rule. Avoid prolonged exposure to moisture.

- Store in a dry, stable environment to prevent warping.

- Handle with care to avoid chipping or deep scratches. Bending against the grain can cause snapping.

Caring for Metal Cards

- Wipe away fingerprints with a microfiber cloth to maintain their shine.

- While extremely durable, the finish can be scratched by abrasive surfaces. It’s best to store them in a dedicated slot in your wallet.

- They are otherwise virtually maintenance-free and built to last.

Direct Material Comparison Tables

Durability and Lifespan Comparison

| Material | Average Lifespan | Scratch Resistance | Water Resistance | Heat Tolerance | Flexibility |

|---|---|---|---|---|---|

| PVC | 3-5 years | Moderate | Excellent | Low (60°C max) | High |

| PET/Composite | 5-7 years | High | Excellent | Excellent (180°C) | Moderate |

| Wood | 2-4 years | Low-Moderate | Poor-Moderate | Moderate | Low |

| Metal | 10+ years | Excellent | Excellent | Excellent | Very Low |

Environmental Impact Comparison

| Material | Recyclability | Biodegradability | Carbon Footprint (Production) | Sustainability Rating |

|---|---|---|---|---|

| PVC | Low | No | Moderate | ★☆☆☆☆ |

| PET/Composite | Moderate-High | No | Moderate | ★★☆☆☆ |

| Wood | High | Yes | Low | ★★★★★ |

| Metal | High | No (but recyclable) | High | ★★★☆☆ |

Which Material Should You Choose? Decision Framework

Still wondering, “What’s the difference between PVC and PET?” or “Are metal cards worth it?” Here’s a simple guide.

- Choose PVC Cards If: Budget is your top priority, you need large quantities, and a 3-5 year lifespan is sufficient.

- Choose PET/Composite Cards If: You need superior durability and heat resistance for lamination, and a longer 5-7 year lifespan justifies a higher cost.

- Choose Wood Cards If: Environmental sustainability is a core brand value and you want a unique, memorable card that stands out.

- Choose Metal Cards If: You are creating an ultra-premium or VIP offering where luxury and long-term durability (10+ years) are the primary goals.

Frequently Asked Questions on PVC vs PET vs Wood vs Metal

1. Which material is most environmentally friendly?

Wood cards made from FSC-certified sources are the most eco-friendly option as they are renewable and biodegradable. However, a durable metal card that lasts 10+ years can have a lower per-year environmental impact than replacing other cards more frequently.

2. Do metal cards work with chip technology?

Yes, but it requires careful engineering. Metal interferes with RFID/NFC signals because it creates a Faraday cage effect. To solve this, manufacturers use hybrid designs with plastic backs or create small, non-metallic windows where the chip can communicate.

3. Are wood cards durable enough for daily use?

A common misconception is that wood cards are fragile. Modern wood cards are made from durable veneers and are surprisingly resilient for everyday use, lasting 2-4 years. However, they are sensitive to moisture and not ideal for wet or harsh environments.

4. Why are PET cards better for lamination?

The simple answer is heat. PET’s molecular structure is far more stable at high temperatures, withstanding up to 180°C. This allows it to pass through the intense heat of a lamination press without warping, melting, or deforming, which is something a standard PVC card cannot do.

5. Which material offers the best print quality?

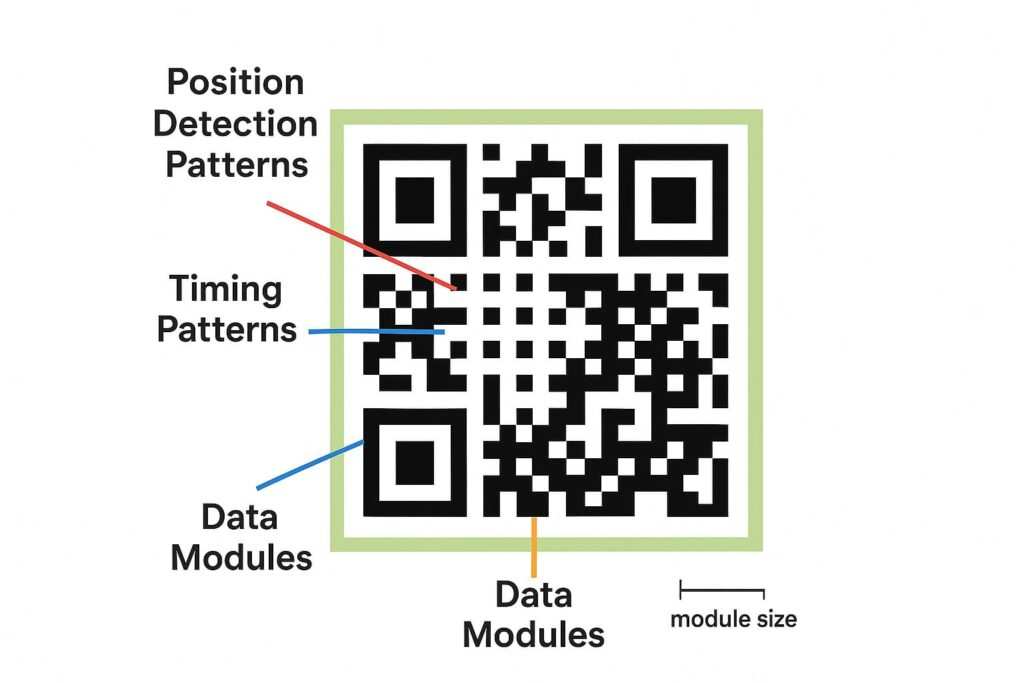

Both PVC and PET offer excellent, vibrant, full-color print quality. The key is using the right printer: direct-to-card dye sublimation printers are perfect for PVC, while high-definition retransfer printers are ideal for PET as they print on a film that is then fused to the card, resulting in true edge-to-edge coverage. For either physical card type, it’s also smart to consider including backup options like well-designed, scannable QR codes.

Conclusion

Choosing between PVC, PET, wood, and metal is a balancing act between durability, cost, environmental impact, and brand image. PVC is the reliable workhorse for everyday needs, while PET/composite cards provide a necessary upgrade in strength and longevity for more demanding applications.

Wood cards offer a powerful way to communicate your brand’s commitment to sustainability with a unique, natural aesthetic. Finally, metal cards provide the ultimate statement in luxury and permanence, reserved for the most exclusive offerings. By considering your primary goal—be it cost-savings, durability, eco-friendliness, or premium positioning—you can confidently select the perfect material that not only serves its function but also strengthens your brand.

Meet Oladepo Babatunde, a technical writer and researcher who makes digital business cards easy to use in the real world. As the founder of CardAdviceHub.com, Oladepo turns tap‑to‑connect tech into clear, reliable workflows—covering NFC/QR setup, troubleshooting, platform comparisons, and practical design tips. He draws on a Higher National Diploma in Computer Science and more than a decade of writing experience since 2014 to test cards, apps, and accessories hands‑on, then share step‑by‑step guides with screenshots, checklists, and templates you can follow in minutes. When he’s not filming tutorials, he’s building resources that help solo creators and teams launch faster—no code required. CardAdviceHub focuses on informational how‑tos and does not publish financial advice.

Areas of focus: NFC tags and chips (NTAG213/215/216), iPhone/Android setup, QR best practices, platform integrations (Sheets, HubSpot, Zapier), event signage and accessories.

How I test: Real devices, repeated tap/read tests with different cases/materials, screenshots and videos for every step, and “first‑try” reliability checks.

Editorial standards: Every how‑to is reproducible, updated when apps change, and clearly labels any affiliate relationships. No financial advice.

Contact: info@cardadvicehub.com (or contact us)